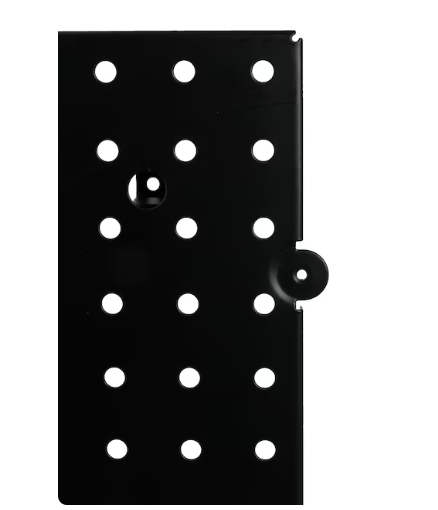

Project Source Steel Pegboard in Black 32-in W x 16-in H

- Steel construction for durable use

- Pegboard panels mount directly to studs or sheet rock

- Fits all standard or heavy-duty peg hooks and accessories

- Mounting screws included

- Peg hooks not included

- Easy to install interconnecting system allows expansion

Transform Your Space, Elevate Your Productivity

In the world of workshop organization, few solutions combine durability, versatility, and aesthetic appeal quite like a quality steel pegboard. Among the various options available today, Project Source steel pegboards stand out as an exceptional choice for both casual DIYers and serious craftspeople looking to maximize their workspace efficiency.

As someone who’s spent countless hours in workshops—from cramped garage corners to spacious professional settings—I’ve learned that the right organizational system can make all the difference between frustration and flow. After using various pegboard systems over the years, I’ve developed a particular appreciation for the Project Source lineup, and I’m excited to share everything you need to know about these workshop game-changers.

The Evolution of Workshop Organization

Remember the days of rummaging through toolboxes, drawers, and bins just to find that one specific wrench or screwdriver? Or perhaps you’ve experienced the classic “I know it’s here somewhere” moment while a project sits half-finished, waiting for you to locate a critical tool. These all-too-common scenarios highlight why proper tool organization isn’t just convenient—it’s essential for productivity.

The humble pegboard has been revolutionizing workshops since the mid-20th century, but today’s steel variants have elevated this simple concept to new heights. No longer just a workshop staple, modern steel pegboards have become design elements in their own right, finding their way into garages, craft rooms, kitchens, and even retail displays.

Let’s dive deep into everything you need to know about Project Source steel pegboards—from specifications and installation to creative applications that might just transform how you think about your workspace.

What Exactly Is a Project Source Steel Pegboard?

At its core, a Project Source steel pegboard is a perforated metal panel designed to provide a customizable hanging system for tools and accessories. Unlike traditional wooden or fiberboard pegboards, these steel variants offer significantly improved durability and weight capacity.

Project Source is a house brand found at major home improvement retailers, known for delivering quality at competitive price points. Their steel pegboards represent a perfect middle ground between budget-friendly options and premium organizational systems.

The defining characteristic of these pegboards is the matrix of evenly spaced holes across the surface, typically arranged in a 1-inch on-center pattern. These holes accommodate various hooks, brackets, and accessories that allow you to create a custom organization system tailored to your specific needs.

What truly sets Project Source steel pegboards apart is their construction quality—featuring commercial-grade steel that strikes an ideal balance between lightweight installation and heavy-duty performance. The steel construction means these boards won’t warp, crack, or deteriorate over time like their wooden counterparts often do, especially in environments with fluctuating humidity levels.

Availability: Where to Purchase Project Source Steel Pegboards

If you’re looking to get your hands on a Project Source steel pegboard, your primary destination should be Lowe’s home improvement stores. As the exclusive retailer for the Project Source brand, Lowe’s carries the complete lineup of these pegboards, along with compatible accessories and mounting hardware.

You can purchase these pegboards in several ways:

- In-store at your local Lowe’s location (where you can examine the quality firsthand)

- Online through Lowe’s website with home delivery options

- Via Lowe’s “Buy Online, Pick Up In-Store” service for those who want to avoid shipping costs

Occasionally, you might find Project Source pegboards through third-party marketplaces like Amazon or eBay, though prices and availability can vary. For the most reliable selection and consistent pricing, going directly through Lowe’s is typically your best bet.

During seasonal sales (particularly around Father’s Day, Black Friday, and spring home improvement promotions), you can often find these pegboards at significant discounts—sometimes up to 25% off regular pricing. Signing up for Lowe’s email newsletters or using their mobile app can help you stay informed about upcoming sales.

Dimensions and Specifications: Finding the Right Size

Project Source steel pegboards come in several standard dimensions to accommodate different workspace needs:

- 16″ × 16″ (ideal for small spaces or creating a modular system)

- 24″ × 24″ (the most popular mid-size option)

- 16″ × 32″ (perfect for narrow wall spaces)

- 32″ × 32″ (for larger workshop applications)

- 16″ × 48″ (designed for vertical tool organization)

The thickness of Project Source steel pegboards is typically 22-gauge (approximately 0.030 inches or 0.76mm), which hits the sweet spot between lightweight handling and structural rigidity. This gauge is substantial enough to support significant weight without making the board unwieldy during installation.

Each pegboard features the industry-standard 1-inch on-center hole pattern, with holes measuring approximately 1/4 inch in diameter. This standardization ensures compatibility with most commercially available pegboard hooks and accessories.

A key specification worth noting is the hole pattern itself. Project Source uses a square pattern rather than the staggered pattern found in some competing products. This square arrangement provides more flexible hook placement options and better accommodates specialty accessories.

For those planning to mount multiple boards together to cover larger areas, Project Source pegboards are designed with edges that align perfectly, allowing for a seamless visual transition between panels.

Weight Capacity: How Much Can These Pegboards Handle?

One of the most significant advantages of steel pegboards over traditional materials is their superior weight capacity. When properly installed, Project Source steel pegboards can reliably support between 50 to 100 pounds per square foot, depending on the mounting method and underlying wall structure.

This impressive capacity means you can confidently hang everything from lightweight precision tools to substantial items like:

- Heavy power drills and impact drivers

- Large wrenches and breaker bars

- Power tool batteries and chargers

- Paint cans and finish supplies

- Gardening equipment

- Automotive parts and accessories

The key to maximizing weight capacity lies in proper installation. When mounted directly to wall studs using appropriate fasteners, these pegboards can reach their full load-bearing potential. For even heavier applications, installing a framework of furring strips between the pegboard and wall can distribute weight more effectively.

It’s worth noting that the weight capacity refers to the board itself—individual hooks have their own weight ratings, typically ranging from 5 to 25 pounds depending on the style and material. For heavier items, specialized double-prong hooks or custom brackets designed specifically for steel pegboards offer enhanced load-bearing capability.

Material Composition: What Makes These Pegboards Special

The core material of Project Source steel pegboards is commercial-grade cold-rolled steel. This material choice delivers several significant advantages:

- Superior durability: Unlike fiberboard or wooden pegboards that can warp, crack, or deteriorate with moisture exposure, steel maintains its structural integrity over decades of use.

- Enhanced strength: The steel construction allows for significantly higher weight capacity per square foot compared to traditional materials.

- Fire resistance: In workshop environments where sparks or heat might be present, steel pegboards provide an added safety advantage.

- Precise hole formation: The manufacturing process for steel pegboards creates clean, consistent holes that maintain their shape even after years of inserting and removing hooks.

The steel undergoes a multi-step surface treatment process before reaching consumers:

- Initial degreasing and cleaning

- Phosphate coating application to improve paint adhesion and corrosion resistance

- Powder-coat paint application, which is more durable than standard liquid paints

- High-temperature curing to create a finish that resists scratching and chipping

This comprehensive treatment process results in a pegboard that not only performs exceptionally well but also maintains its appearance over years of workshop use.

Mounting Hardware: What’s Included and What You’ll Need

Project Source steel pegboards typically come with basic mounting hardware, though the specific components can vary between package configurations. Most standard packages include:

- Mounting screws (usually #10 x 1-1/2″ wood screws)

- Plastic wall anchors for installation in drywall

- Small plastic spacers to create the necessary gap between the pegboard and wall

- Basic installation instructions

While this included hardware is sufficient for basic installation, many users opt to supplement with additional components for enhanced stability and functionality:

- Furring strips (1″ × 2″ wood pieces) to create more substantial spacing behind the board

- Heavy-duty toggle bolts for installation on hollow walls

- Construction adhesive for additional security when mounting to concrete or masonry

- Finishing washers to distribute screw pressure and improve appearance

It’s worth noting that specialized mounting frames are also available for purchase separately. These frames create an integrated spacer system around the perimeter of the board, simplifying installation while providing optimal hook clearance behind the pegboard.

Installation Process: Getting Your Pegboard Up and Running

Installing a Project Source steel pegboard is a straightforward process that even novice DIYers can handle with basic tools. Here’s a comprehensive step-by-step guide:

Step 1: Planning and Preparation

Begin by determining the optimal location for your pegboard. Consider these factors:

- Proximity to your work area

- Available wall space

- Stud locations (using a stud finder)

- Height placement for comfortable access

- Clearance for protruding tools

Measure and mark the intended installation area, ensuring you have adequate space for the pegboard dimensions.

Step 2: Creating the Mounting Framework

For optimal hook placement and stability, you’ll need to create space between the pegboard and the wall. There are two primary approaches:

Option A: Using Spacers

- Mark stud locations on the wall

- Position the pegboard and mark screw locations (ideally hitting studs)

- Pre-drill holes in the pegboard at marked locations

- Place spacers between the pegboard and wall at each screw location

Option B: Installing Furring Strips (Recommended)

- Cut 1″ × 2″ furring strips to match the pegboard dimensions

- Attach furring strips horizontally to wall studs using 2″ wood screws

- Space strips approximately 16″ apart vertically

- Ensure strips are level using a carpenter’s level

Step 3: Mounting the Pegboard

- Position the pegboard against the furring strips or spacers

- Verify the board is level

- Secure the pegboard to the furring strips using the provided screws

- If using the spacer method, ensure screws penetrate wall studs where possible

- For additional security, add screws around the perimeter of the board

Step 4: Finishing Touches

- Inspect all mounting points to ensure the board is secure

- Verify that there’s adequate clearance behind the board for hook placement

- Consider adding frame molding around the perimeter for a more finished appearance

- Clean the pegboard surface of any drill dust or fingerprints

Tools Required for Installation

The installation process requires only basic tools that most homeowners already have on hand:

- Tape measure

- Pencil for marking

- Stud finder

- Drill with appropriate bits

- Screwdriver (Phillips head)

- Level

- Saw (if cutting furring strips)

- Safety glasses

- Hammer (occasionally needed)

For more complex installations, these additional tools can be helpful:

- Circular saw or miter saw (for precise cutting of furring strips)

- Impact driver (for driving screws into harder materials)

- Masonry drill bits (for concrete or brick wall mounting)

Durability Factors: Rust Resistance and Longevity

One common concern with steel workshop components is their susceptibility to rust and corrosion. Project Source addresses this by incorporating multiple protective measures into their steel pegboards:

The pegboards feature a zinc phosphate undercoating that serves as the first line of defense against corrosion. This is followed by a powder-coat paint finish that provides both aesthetic appeal and substantial moisture resistance.

While not technically classified as “outdoor rated,” these pegboards do offer impressive rust resistance for indoor and covered settings. Users report excellent performance in:

- Garages with typical humidity fluctuations

- Basements with moderate moisture levels

- Covered patios and workshop areas

- Utility rooms and laundry areas

For environments with extreme moisture exposure, additional protective measures can extend the pegboard’s lifespan:

- Applying a clear enamel sealer over the factory finish

- Installing in locations with adequate air circulation

- Using dehumidifiers in particularly damp workshops

- Periodically wiping down the surface with a silicone-based protectant

With proper care, a Project Source steel pegboard can easily last 15+ years without significant deterioration—far outlasting traditional wood or fiberboard alternatives.

Versatility: Indoor and Outdoor Applications

While primarily designed for indoor use, Project Source steel pegboards demonstrate impressive versatility across different environments when properly installed and maintained.

Ideal Indoor Applications:

- Workshops and garages

- Craft rooms and sewing spaces

- Home offices for organizing supplies

- Kitchens for pots, pans, and utensils

- Closets and laundry rooms

- Retail displays and commercial settings

Potential Outdoor Applications (with additional protection):

- Covered porches and patios

- Garden sheds with minimal moisture exposure

- Covered outdoor workstations

- Screened porches and three-season rooms

For outdoor applications, consider these additional protective measures:

- Mount under adequate overhang or roof coverage

- Apply marine-grade clear coat before installation

- Use stainless steel mounting hardware

- Install a thin bead of silicone caulk around the perimeter

- Position away from direct sprinkler or rainfall exposure

Several users report successfully using these pegboards in semi-outdoor settings for years without significant deterioration, particularly in drier climates.

Color Options and Aesthetic Considerations

Project Source steel pegboards are available in several color options to complement different workshop aesthetics and preferences:

- Classic White: The most common option, offering a clean, bright surface that makes tools easy to locate

- Industrial Gray: A practical option that conceals dust and fingerprints

- Matte Black: Perfect for modern workshops and contrasting with bright-colored tools

- Navy Blue: A less common but distinctive option available in select markets

- Red: Occasionally available as a special purchase item

The powder-coat finish provides a uniform, slightly textured surface that reduces glare and resists scratching. This finish is substantially more durable than painted surfaces on traditional pegboards.

For those seeking customization, these pegboards can be repainted using high-quality spray paint designed for metal surfaces. The process typically involves:

- Light sanding of the original finish

- Application of a bonding primer

- Multiple light coats of your chosen color

- Optional clear protective top coat

Many workshop enthusiasts have created striking visual systems by color-coding pegboards based on tool categories or work zones, adding both organizational clarity and aesthetic appeal.

Accessories: Hooks, Brackets, and Organization Systems

One of the greatest strengths of Project Source steel pegboards is their compatibility with a wide range of accessories. While some come with starter hook sets, most are sold separately to allow for customized organization solutions.

Standard Accessories Compatible with Project Source Pegboards:

Hooks and Pegs:

- Standard J-hooks in various lengths

- L-hooks for heavier items

- Double-arm hooks for larger tools

- Loop hooks for hanging cables and hoses

- Curved hooks for oddly shaped items

Brackets and Holders:

- Screwdriver holders with multiple slots

- Drill holders with adjustable widths

- Plier racks with individual slots

- Shelf brackets for creating small storage areas

- Container brackets for parts and small components

Specialized Accessories:

- Paper towel holders

- Spray can holders

- Magnetic tool bars

- Small parts bins that mount directly to the pegboard

- Specialized holders for specific power tools

Project Source offers their own line of pegboard accessories, but the standard hole pattern ensures compatibility with hooks and brackets from other manufacturers like Stanley, Craftsman, and Everbilt.

For maximum utility, consider creating zones on your pegboard with specific accessory types grouped together—for example, keeping all screwdrivers in one section, measuring tools in another, and power tool accessories in a third.

Pegboard Thickness and Structural Considerations

The standard thickness of Project Source steel pegboards (22-gauge or approximately 0.030 inches) represents a carefully calculated balance between rigidity and weight.

This thickness provides several advantages:

- Sufficient strength to prevent bending or deformation under normal loads

- Light enough for one person to handle during installation

- Rigid enough to maintain flatness against the wall

- Substantial enough to provide secure anchoring for hooks

The pegboard’s structural integrity is further enhanced by a series of subtle reinforcement ridges pressed into the metal during manufacturing. These ridges, often visible on the back of the pegboard, provide additional resistance to bending and warping.

For applications requiring exceptional rigidity, some users opt to install a backing frame of aluminum angle stock around the perimeter of the board. This creates a reinforced frame that virtually eliminates any potential for bending, even with very heavy tools.

Hook Compatibility: Standard vs. Specialized Options

One of the most important considerations when selecting a pegboard system is hook compatibility. Project Source steel pegboards use the industry-standard 1/4-inch hole diameter with 1-inch on-center spacing, ensuring broad compatibility with most commercially available pegboard accessories.

Compatible Hook Types:

Standard Steel Hooks:

These basic hooks feature a straight shaft that inserts into the pegboard hole and a slight bend at the upper portion that prevents the hook from pulling straight out. These work well with Project Source pegboards but may require occasional readjustment.

Locking Hooks:

These advanced hooks include special features that prevent them from lifting out during tool removal. They typically use one of several mechanisms:

- Spring-loaded locking tabs

- Twist-to-lock designs

- Rubber or plastic friction components

Specialized Steel Pegboard Hooks:

Designed specifically for metal pegboards, these hooks often feature:

- Slightly larger diameter shafts for more secure fit

- Extended retaining portions for better stability

- Reinforced bends to support heavier loads

While most standard pegboard hooks work adequately with Project Source pegboards, many users report that hooks specifically designed for metal pegboards provide superior stability and reduced “pop-out” during tool removal.

For maximum security, especially with expensive or frequently used tools, consider investing in locking-style hooks that physically secure to the pegboard.

Cost Considerations: Investment vs. Value

Project Source steel pegboards represent a mid-tier price point in the pegboard market, offering an excellent balance of quality and affordability.

Current pricing (as of late 2024) typically falls within these ranges:

- 16″ × 16″ panels: $15-$20

- 24″ × 24″ panels: $25-$30

- 32″ × 32″ panels: $35-$45

- 16″ × 48″ panels: $30-$40

These prices position Project Source pegboards as more expensive than basic hardboard options but significantly more affordable than premium all-steel organizational systems from brands like Gladiator or Wall Control.

When considering the long-term value, several factors make these pegboards an excellent investment:

- Significantly longer lifespan compared to wood-based alternatives

- No warping or deterioration in humid environments

- Higher weight capacity reducing the need for additional storage solutions

- Compatibility with a wide range of accessories for future expansion

For a complete organizational system, budget for additional components beyond just the pegboard:

- Hook assortment: $15-$30 (basic starter set)

- Specialized holders: $5-$15 each

- Mounting hardware: $5-$10 (if upgrading from included hardware)

- Framing materials: $10-$20 (for optimal installation)

Many users find that investing in quality up front ultimately saves money compared to replacing inferior pegboard systems multiple times over the years.

Heavy-Duty Applications: Pushing the Limits

For those with serious organizational needs, Project Source steel pegboards excel in heavy-duty applications that would quickly damage or destroy traditional pegboards.

When properly installed with furring strips attached to wall studs, these pegboards can reliably handle tools and equipment that would be unthinkable on standard hardboard pegboards:

- Large framing hammers and demolition tools

- Full socket sets with rails

- Power tool batteries and chargers

- Multiple gallon paint cans

- Automotive repair equipment

- Heavy garden tools like post hole diggers

For extreme heavy-duty applications, consider these enhancement strategies:

- Double up on mounting screws, ensuring each penetrates a wall stud

- Use construction adhesive between furring strips and the wall

- Install additional vertical furring strips at 12″ intervals rather than the standard 16″

- Select heavy-duty hooks rated for maximum weight capacity

- Distribute heavier items across multiple hooks

- Install additional pegboards to distribute the overall load

Many professional mechanics and contractors report successfully using Project Source pegboards in commercial settings where durability and weight capacity are essential requirements.

Warranty and Consumer Protection

Project Source steel pegboards typically come with a limited warranty that covers manufacturing defects and premature finish failure. The specific terms may vary, but most include:

- 1-year limited warranty against manufacturing defects

- Coverage for premature rust or corrosion under normal indoor use

- Protection against delamination of the powder-coat finish

To maintain warranty coverage, be sure to:

- Keep your receipt or proof of purchase

- Install according to the manufacturer’s instructions

- Use only in environments suitable for the product

- Avoid modifications that could compromise structural integrity

Beyond the manufacturer’s warranty, purchasing through major retailers like Lowe’s often provides additional consumer protections and satisfaction guarantees.

For maximum protection, some consumers opt to purchase these pegboards using credit cards that offer extended warranty protection, effectively doubling the coverage period for potential defects.

Comparative Analysis: Steel vs. Traditional Pegboards

When evaluating pegboard options, understanding the relative strengths and limitations of different materials helps inform the best choice for your specific needs.

Steel Pegboards (Project Source) vs. Hardboard Pegboards:

Durability:

- Steel: Excellent resistance to moisture, impacts, and temperature changes

- Hardboard: Susceptible to warping in humid environments, deteriorates over time

Weight Capacity:

- Steel: 50-100 pounds per square foot

- Hardboard: 10-25 pounds per square foot

Longevity:

- Steel: 15+ years with minimal degradation

- Hardboard: 3-7 years before replacement is typically needed

Aesthetic Appeal:

- Steel: Clean, modern appearance with consistent finish

- Hardboard: Traditional workshop look, but prone to showing wear

Cost:

- Steel: Higher initial investment ($1.50-$2.50 per square foot)

- Hardboard: Lower initial cost ($0.50-$1.00 per square foot)

Steel Pegboards vs. Plastic Pegboards:

Strength:

- Steel: Superior rigidity and weight capacity

- Plastic: Moderate strength, can flex under heavier loads

Moisture Resistance:

- Steel: Good resistance with proper coating

- Plastic: Excellent resistance, will not rust

Temperature Stability:

- Steel: Maintains integrity in extreme temperatures

- Plastic: May become brittle in cold or soft in heat

Installation Ease:

- Steel: Requires careful mounting to support weight

- Plastic: Often features integrated mounting systems for easier installation

Environmental Impact:

- Steel: Potentially recyclable, longer lifespan

- Plastic: Less recyclable, petroleum-based product

For most serious workshop applications, the additional investment in steel pegboards like Project Source delivers substantial long-term value through extended lifespan and superior performance.

Expandability: Creating Larger Systems

One of the significant advantages of Project Source steel pegboards is their modular nature, allowing users to create expansive organizational systems by combining multiple panels.

Effective Methods for Connecting Multiple Pegboards:

Edge-to-Edge Installation:

- Mount pegboards directly adjacent to each other

- Ensure consistent spacing between all mounting points

- Align holes precisely for a seamless appearance

- Consider using connecting brackets between panels

Grid Configurations:

- Create larger rectangular or square arrangements

- Maintain consistent spacing between all panels

- Use a common mounting framework for perfect alignment

- Consider color variations between panels for visual organization

Split-Level Installations:

- Mount pegboards at different heights for various tool types

- Create workstation zones for different activities

- Combine with shelving or cabinets for integrated storage

- Use consistent spacing techniques across all levels

For the cleanest appearance when combining multiple panels, consider these professional techniques:

- Install thin trim pieces between panels to cover any slight gaps

- Use a consistent mounting framework behind all panels

- Ensure perfectly level installation using laser levels

- Consider color-coding different sections for organizational clarity

Many workshop enthusiasts have created impressive wall-spanning systems using six or more panels in creative configurations, effectively transforming entire workshop walls into customizable tool organization systems.

Customer Experiences: What Users Are Saying

The real test of any product comes from those who use it daily. Based on aggregated reviews and feedback, here’s what customers consistently report about Project Source steel pegboards:

Positive Feedback Highlights:

Durability:

“After five years in my humid garage, this pegboard looks exactly like it did on day one. My old hardboard pegboard lasted barely two years before warping.”

Weight Capacity:

“I’ve got my entire mechanic’s tool set hanging on this—wrenches, socket sets, everything—and it hasn’t budged an inch.”

Appearance:

“The clean look really upgraded my workshop. I actually enjoy keeping tools organized now because it looks so good.”

Versatility:

“I started with one panel in my garage and now have them in my craft room, laundry area, and garden shed. They work great everywhere.”

Value:

“Spent about twice what my hardboard pegboard cost, but five years later, it’s still perfect while I would have replaced the cheap one twice by now.”

Common Criticisms:

Installation Complexity:

“Needed more preparation than expected. Definitely need to use furring strips for the best results.”

Hook Security:

“Standard hooks can pop out sometimes when removing tools. Had to upgrade to locking-style hooks for frequently used items.”

Initial Cost:

“More expensive up front compared to basic pegboards, though the durability makes up for it long-term.”

Weight During Installation:

“Heavier than expected, making solo installation a bit challenging for larger panels.”

The overwhelming consensus among users indicates high satisfaction rates, with most criticisms focused on installation challenges rather than the product’s performance once installed.

Conclusion: Is a Project Source Steel Pegboard Right for You?

After thoroughly examining every aspect of Project Source steel pegboards, it’s clear that they represent an excellent organizational solution for a wide range of applications. Their combination of durability, weight capacity, and aesthetic appeal makes them stand out in the crowded workshop organization market.

These pegboards are particularly well-suited for:

- Serious DIY enthusiasts who value long-term durability

- Workshops in humid environments where wood-based alternatives would deteriorate

- Mechanics and professionals who need to organize heavy tools

- Anyone looking to create a clean, organized workspace with visual appeal

- Those willing to make a slightly higher initial investment for superior long-term value

While the initial cost exceeds basic pegboard options, the extended lifespan and enhanced functionality typically deliver greater value over time. Most users report high satisfaction with their investment, particularly appreciating the freedom from warping and deterioration common with traditional pegboards.

Whether you’re organizing a small home workshop or equipping a professional garage, Project Source steel pegboards offer a reliable, attractive solution that will likely serve your organizational needs for many years to come.

For workshop enthusiasts serious about organization, investing in quality tools for storing your tools simply makes sense—and Project Source steel pegboards represent one of the most practical investments you can make in creating an efficient, organized workspace.